The most flexible machine types, is designed for the economical and efficient surface treatment of a variety of workpieces.

Application

Cleaning for forged parts, pumps and fittings.

Decorative blasting for nonferrous metal surfaces

Deburring for die casting and stamped parts, etc.

Advantages

Can be loaded with another new batch of workpieces while machine is in being processed.

Quick turnaround and easy assembly.

Highly efficient blast wheels.

Automatic PLC control.

Multiple machine sizes and variations available.

Technical Data

| Machine Type | ORB-10/12 | ORB-12/16 | ORB-12/20 |

| No. of blast wheels | 2 | 2 | 3 |

| No. of wheels and capacity (kW) | 2×7.5 | 2×11 | 3×11 |

| Max dia of workpiece batch (mm) | 1000 | 1200 | 1200 |

| Max height of workpiece (mm) | 1200 | 1600 | 2000 |

| Max weight of workpiece (kg) | 250 | 350 | 500 |

| Abrasive initial feeding(kg) | 450 | 600 | 900 |

| Electronic connection power (kW) | 22 | 29 | 42 |

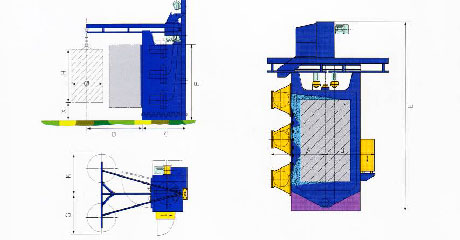

Photo & Drawing